|

Charging

Correct battery charging ensures the maximum possible working life for the battery.

There are four major method of charging.

1.Constant Voltage Charging

2.Constant Current Charging

3.Two stages charging

4.Trickle Current Charging

Constant Voltage Charging

This is the recommended method of charging for VRLA batteries. It is necessary to closely control the actual voltage to ensure it is within the limits advised.

Standby Service: 2.23-2.30 vpc at 25℃.

Cycle Service : 2.40-2.45 vpc at 25℃.

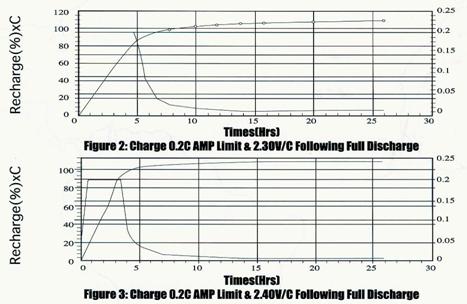

It is suggested that the initial current be set within 0.4C Amps. The attached graph indicate the time taken to fully recharge battery. It should be noted the graph illustrated is for a fully discharged battery, i.e; a battery that has reached the minimum cell voltage recommended for its discharge time. It is also seen that it is necessary to indicate that the battery is fully charged is approx 5Ma/Ah under charging voltage is 2.30 vpc.

Note: It is necessary to ensure that the voltage is correctly set. A charging voltage set too high will increase the corrosion of the positive plates and shorten battery life. a charging voltage set too low will lead to sulphation of the plates causing loss of capacity and ultimately shortening the life of the battery.

Constant Current Charging

This method of charging is generally not recommended for VRLA batteries, It is necessary to understand that if the batteries are not removed from the charger as soon as possible after reaching a stats of full charge. Considerable damage will occur to the batteries due to overcharging.

Two Stages Charging

This method should not be used where the battery and load are connected in parallel, If this

method is to be used. It is suggested that G-BATT VRLA department is contacted.

Trickle Current Charging

This method is not recommended for VRLA batteries, however, if this method is to be used,

It is suggested that the G-BATT VRLA technical department is contacted.

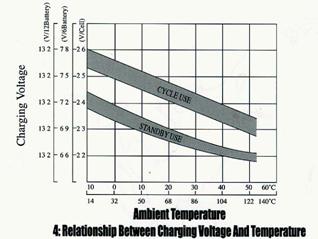

Effect of Temperature on charging Voltage

As temperature rising, electrochemical activity in a battery increase, similarly, as temperature

falling, Electrochemical activity decreases. Therefore, as temperature rising charging voltage

should be reduced to prevent overcharge and reverse increase as temperature falls to avoid

undercharge, in general, to assure design service life, a charger with temperature compen-

sation function is recommended to be used. the recommended compensation factor for

G-BATT VRLA batteries is ±3mV/℃/Cell (standby use) and ±4 mV/℃/Cell (cycling use). the

standard center point for temperature compensation is 20℃. Figure 4 shows the relationship

between temperature and charging voltage in both cyclic and standby applications.

Effect of Voltage on battery gassing

Although the batteries are of the recombination type and the amount of gassing at normal operating voltage and temperature is negligible, if the charging voltage is increased, Gassing will occur despite the recommended design of the product. Gassing does not normally occur while the battery is operating under float conditions and normal constant voltage recharge of 2.23-2.30vpc at 25℃, very little gassing occur when the battery is recharged under normal cycling recharge procedures. However it can be seen on the accompany graph the higher voltage that this especially under conditions of constant current charging will substantially increase the volume of gas.

|